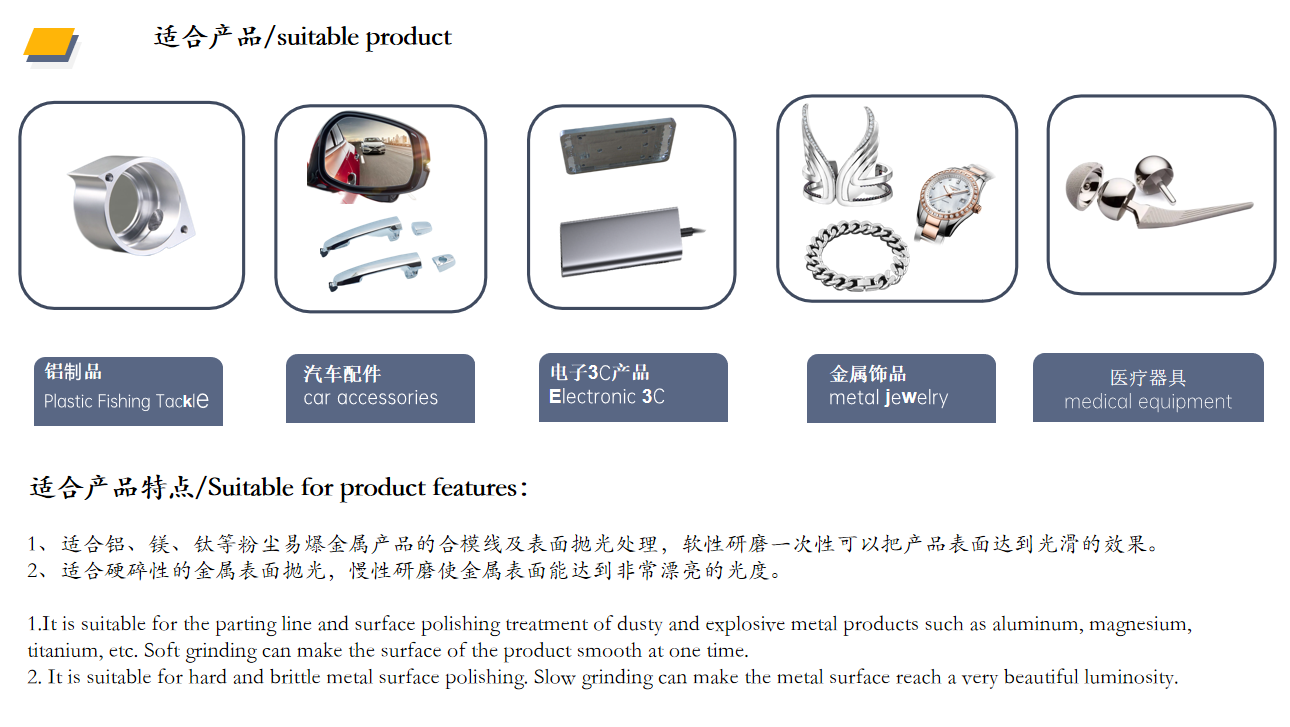

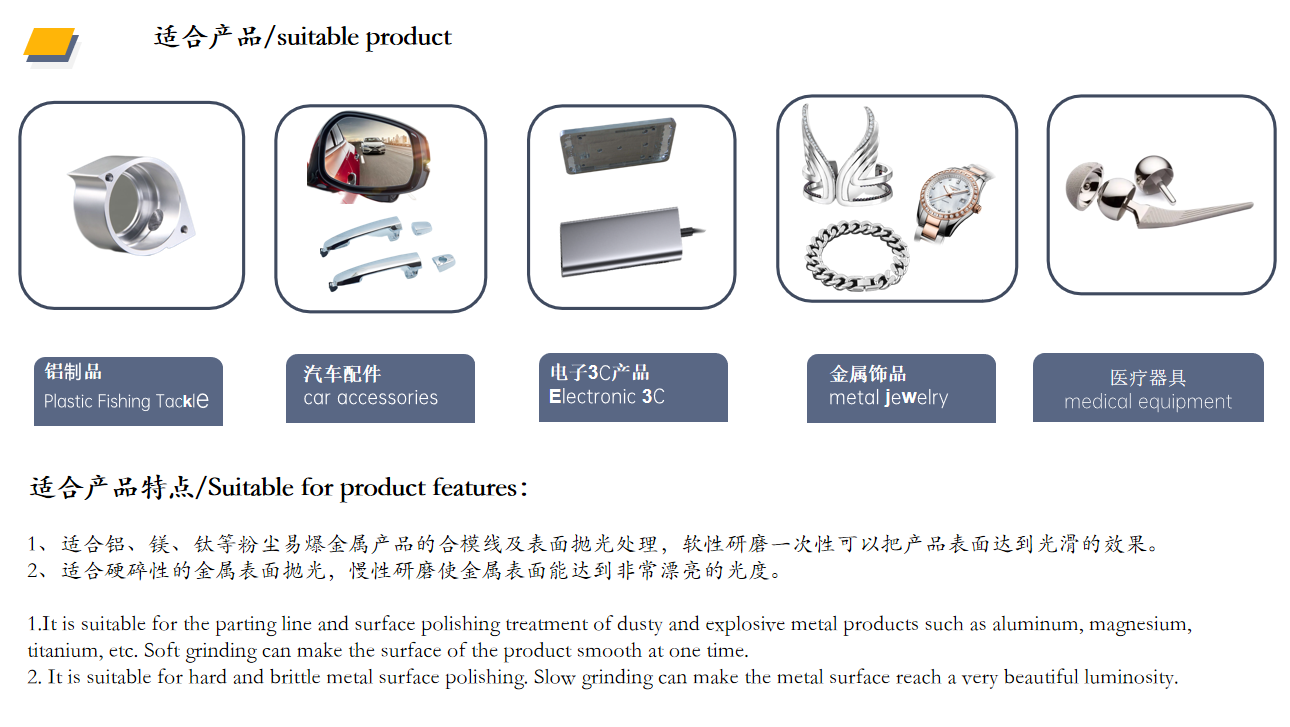

Applicable scope:This product is suitable for surface grinding and polishing of plastic, soft metal, hard metal, acrylic and other products.

Mode: manual grinding, automatic grinding

Polishing machine commonly used in medical device industry

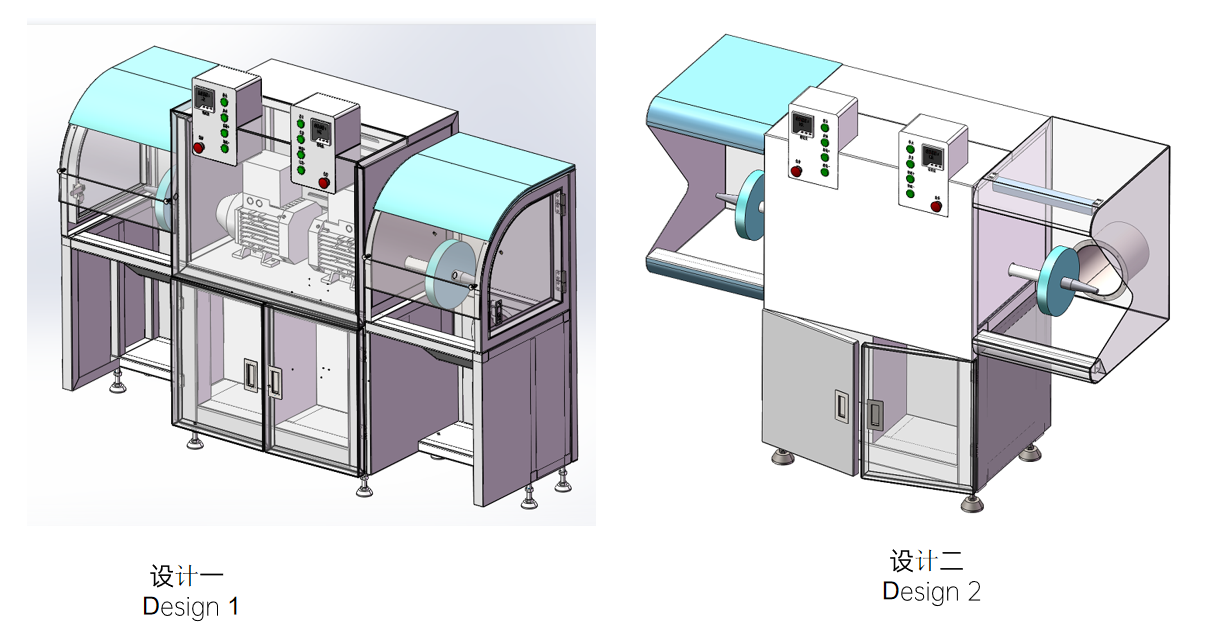

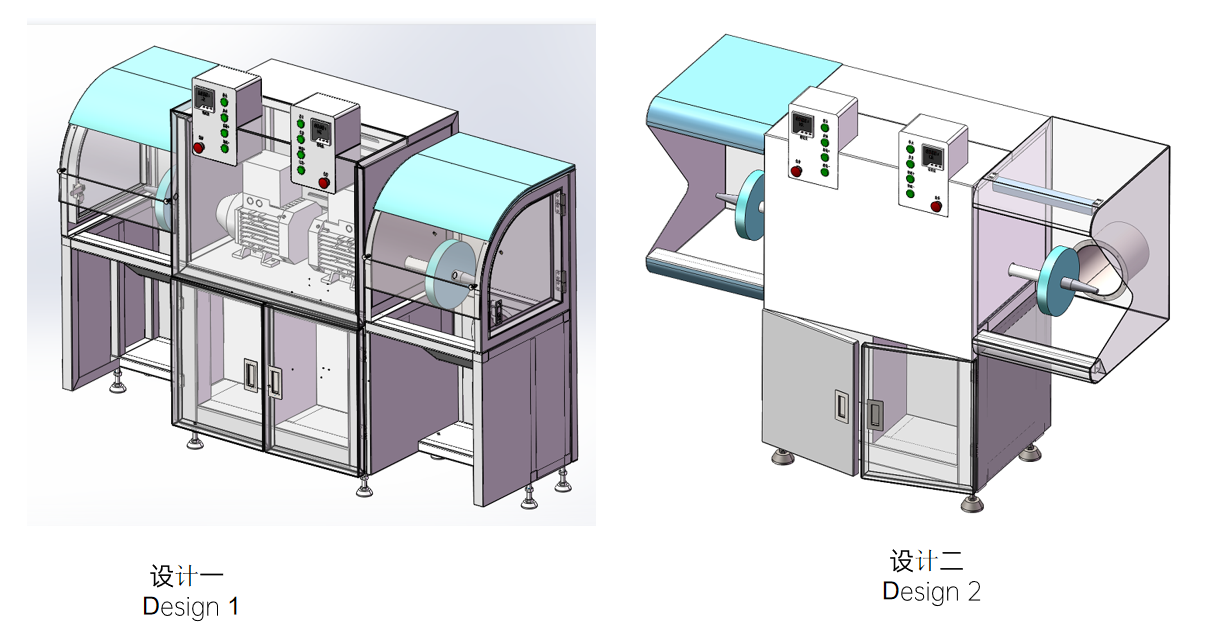

exterior design

The appearance is made of pure white paint, and the appearance design is beautiful and elegant. The working position is designed according to ergonomics, taking into account the comfort of the workers for sedentary work and the suitability of the grinding posture. The dust falling during grinding can be cleaned in time every day by disassembling the tray device, which ensures that the equipment is easy to clean and conforms to the clean management system of the factory. The design tool is attached to the cover box, and workers can place sundries when they are not working at the post, and use the job post standard to organize.

1. Parameter adjustment: the speed is electronically controlled, non-mechanism adjustment 2. A dust collection box is installed at the bottom of the equipment, and a dust discharge port is provided at the rear. The outer diameter of the dust discharge port is 200mm. Post-processing guides Wuhan Mindray in the pipeline installation layout; 3. The processing process of the equipment is stable, and the stable working time is >3000 hours; 4. The motor speed is adjusted by frequency conversion, the speed adjustment range is 800~2800r/min adjustable, and the speed adjustment accuracy requires ±5r/min; 5. The thickness of the shell of the grinding and polishing equipment is ≥ 3mm, and the material is carbon steel 6. Circuit breaker, contactor, relay: Schneider/ABB/Omron 7. The equipment itself meets the explosion-proof requirements of aluminum-magnesium-titanium alloy, and the electrical components meet the explosion-proof requirements of aluminum-magnesium-titanium dust (electrical control box, motor, lighting and control buttons)