Ganma Technology Co., Ltd. was established in May 2017 and is located in Guangzhou, China. The company is committed to the R&D and production of automated polishing equipment and the application of polishing wheels. Provides polishing for various metal surfaces and provides a series of polishing solutions for metal surfaces in various industries.

The company has a professional and experienced development team with rich automation experience, insisting on developing new equipment based on customer needs, focusing on reducing labor and reducing customer costs. Optimize polishing processes and grinding systems in various metal polishing industries. Team members have been engaged in the polishing and grinding consumables and machine industry since the early 1990s, and are very familiar with the polishing and grinding processes of various material products. The combination of fully automated equipment and experience in the polishing and grinding industry makes us highly competitive in the integration of equipment and consumables. And it can promote the fully automated and intelligent process of the polishing industry.

Since its establishment, the company has applied for 2 invention patents and 13 utility model patents. The equipment developed includes: high-speed polishing machine, dual-station five-axis linkage polishing machine, plastic mold clamping line polishing, etc.

In terms of polishing consumables: We insist on independent research and development and production of high-quality polishing cloth wheels and polishing wax. High quality and excellent price are our pursuit of consumables.

The company's main service industries: metal products and processing, automobile and transportation equipment manufacturing, furniture production, bathroom products and accessories, piano and musical instrument manufacturing, medical equipment, watch industry, 3C products and other industries that require metal surface polishing.

Founded in 2006, Yiliang Grinding, an export-focused company, has worked closely with many foreign customers for many years. Our customers have consistently high standards for us, and we always strictly follow international standards for product quality.

We are committed to building a company specializing in metal surface polishing and grinding equipment with high requirements for quality, technology and service.

Robotic polishing

Robotic polishing

1. The robot grabs the product and grinds or polishes it.

According to the product selection, a robot without weight parameters is used to grab the product and polish it on a grinder or polishing machine.

2. Manipulator cooperates with special machine equipment to load and unload materials

Applicable products: single products that cannot be polished by standard machines or in batches. Suitable for grinding, drawing, deburring and polishing of products made of most materials.

Industry: Mainly used for assisting in polishing various metal products, plastic products, mechanical parts, production products, medical equipment and other special-shaped products

Improve polishing quality and product finish to ensure product consistency

Improve production efficiency and can produce continuously 24 hours a day.

Improve workers' working conditions and enable them to work in harmful environments for a long time.

Reduce the requirements for operators’ grinding and polishing skills. Reduce labor costs and recruitment difficulty

The flexibility of the manipulator shortens the cycle of product modification and replacement and reduces the corresponding investment in equipment.

The manipulator has strong developability and can be programmed and used again.

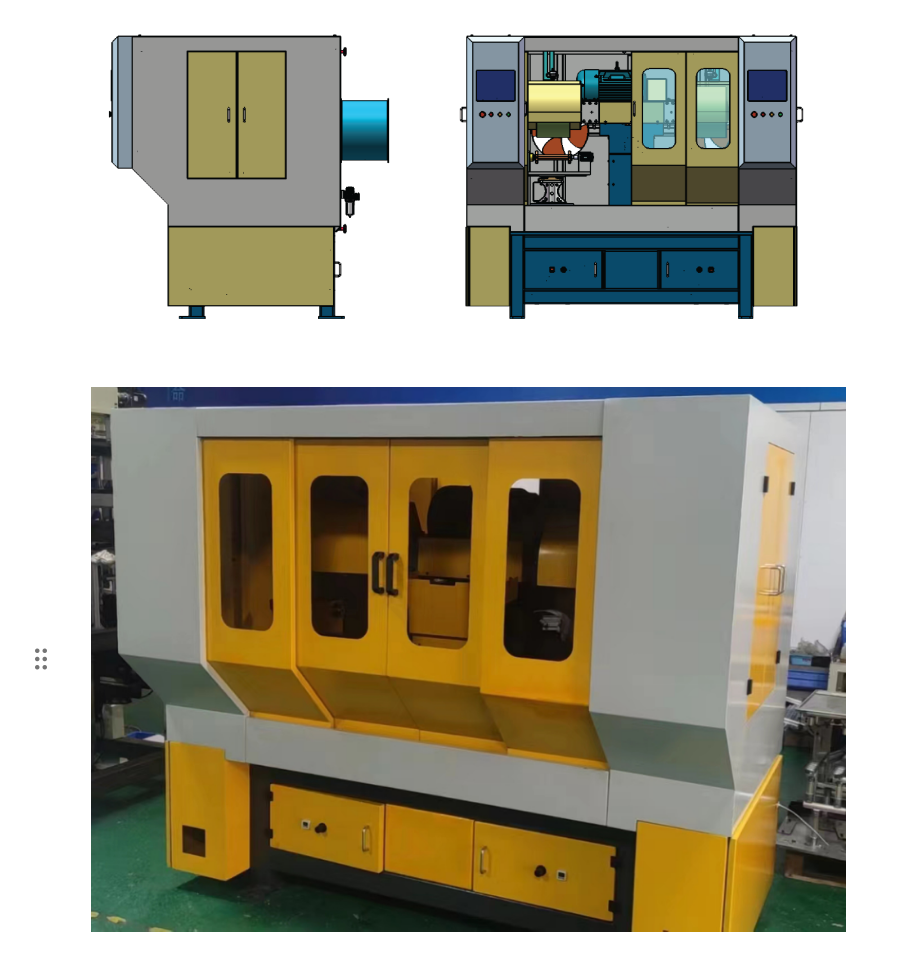

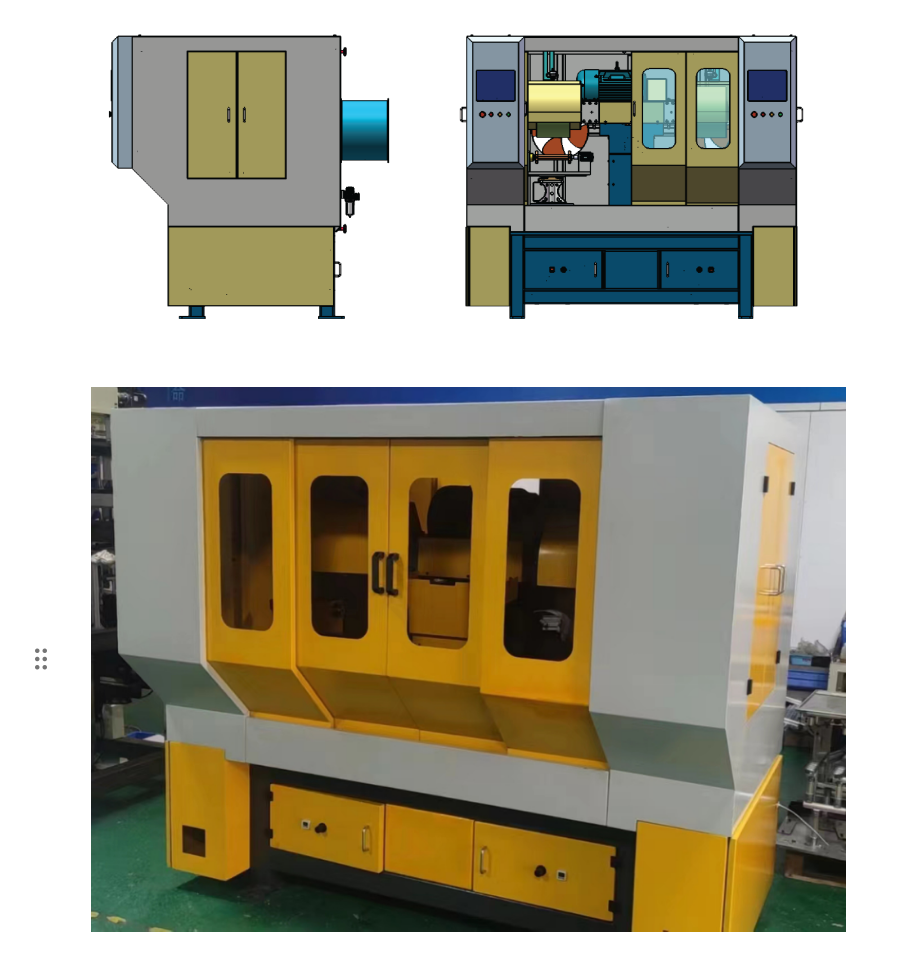

Single/double station four-axis/five-axis fully automatic metal mirror polishing machine

1. Special digital control system for grinding with friendly interface. Visual, standardized, digital operating system, easy to operate, no matter how many workpieces are input at one time, no need for repeated adjustments.

2. It can realize 4/5-axis linkage (Y-axis, Z-axis, A-axis, C-axis, E-axis, The unit is 0.1 degrees. A variety of grinding modes can be , and the grinding time and frequency can be set freely.

3. Automatic liquid wax spray system, one wax barrel and one spray gun, safe and reliable.

4. A variety of polishing wheel grinding and abrasive belt grinding groups can be to meet different workpiece effect requirements.

5. Grinding method: When the equipment presses the start button, the workpiece will automatically go under the grinding wheel and start grinding. After completing the set grinding, it will automatically exit and return to facilitate loading and unloading of the workpiece.

6. Closed dust cover, two suction ports, strong suction power.

7. Digital display of air pressure and low pressure alarm device.

8. Fully enclosed protective cover to ensure operator safety.

1. This machine is suitable for fine grinding with high precision requirements. The accuracy error of surface grinding is plus or minus 0.05MM.

2. The main transmission components are all cast parts, which have high stability. The abrasive belt pressure plates are all made of soldered steel, which is durable.

3. It has good cooling performance, is dust-proof, and can easily clean the powder produced after polishing, and can well protect the health of the workpiece.

4. The work is easy to operate and no professional skills are required.

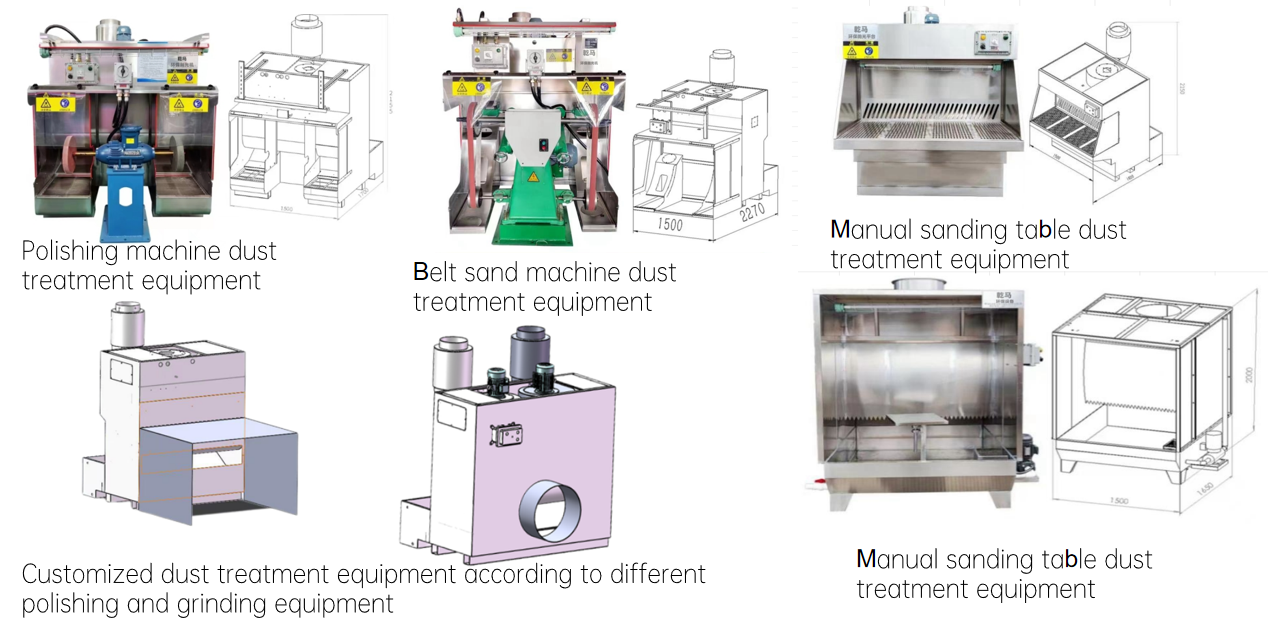

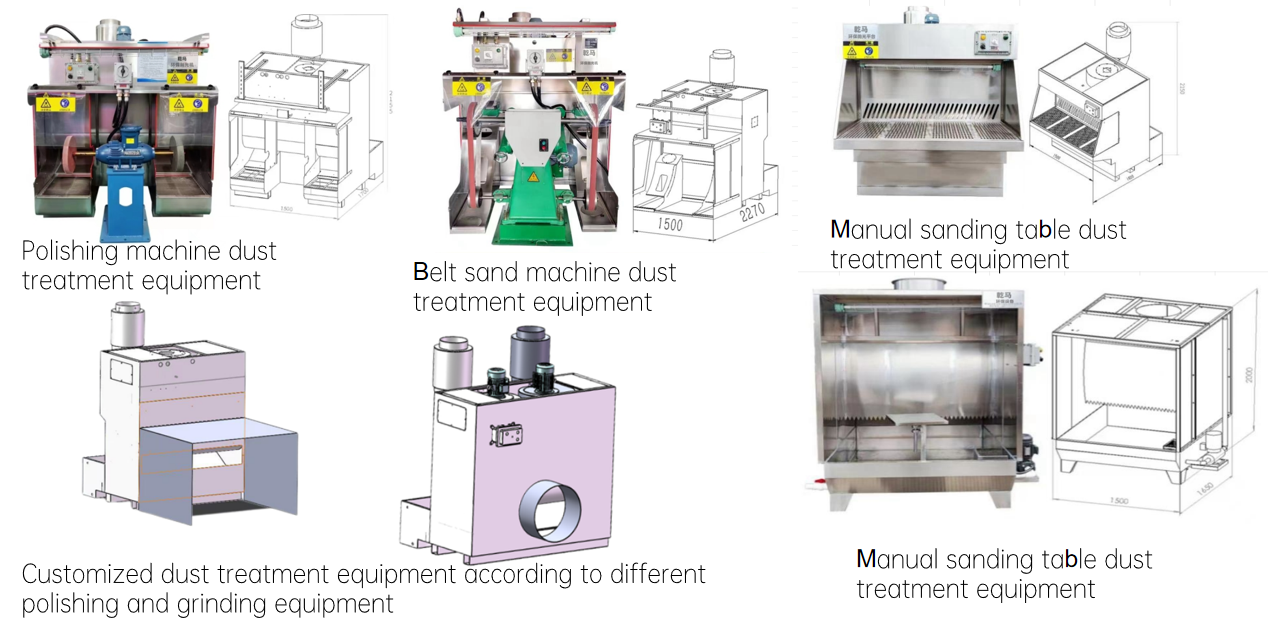

Explosion-proof and environmentally friendly water curtain dust treatment equipment

Explosion-proof and environmentally friendly water curtain dust treatment equipment

Different dust handling equipment can be customized according to requirements.

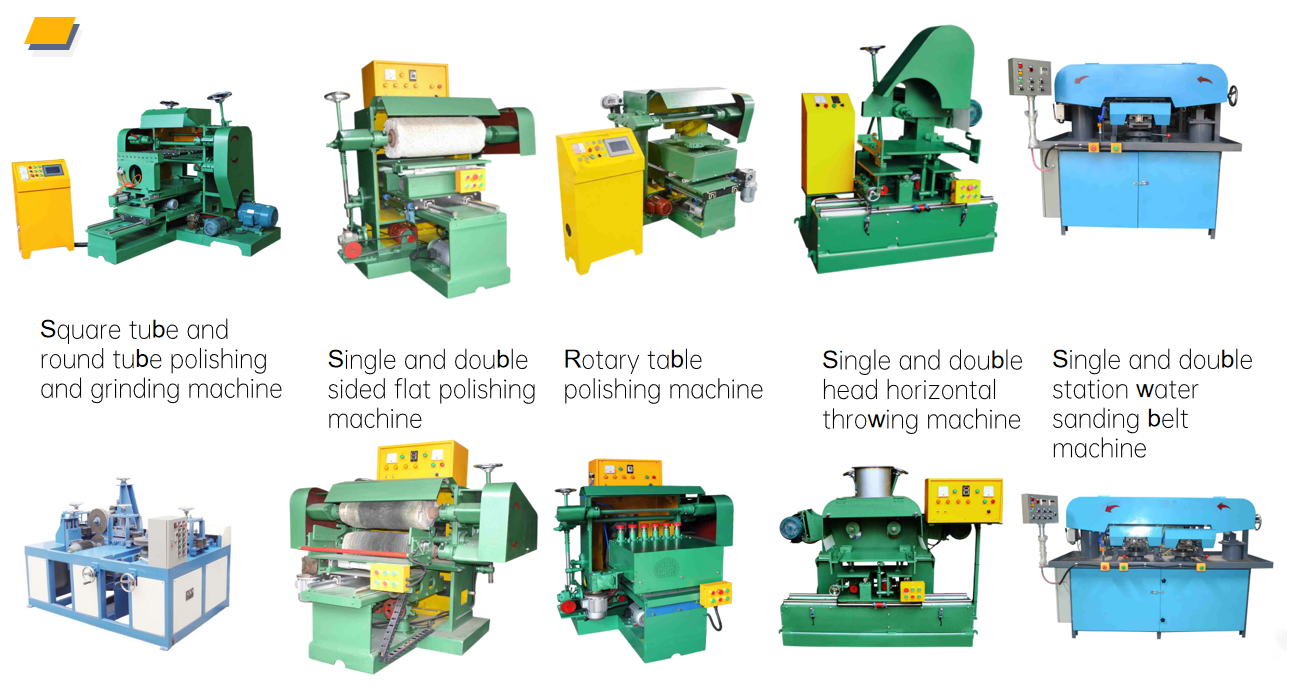

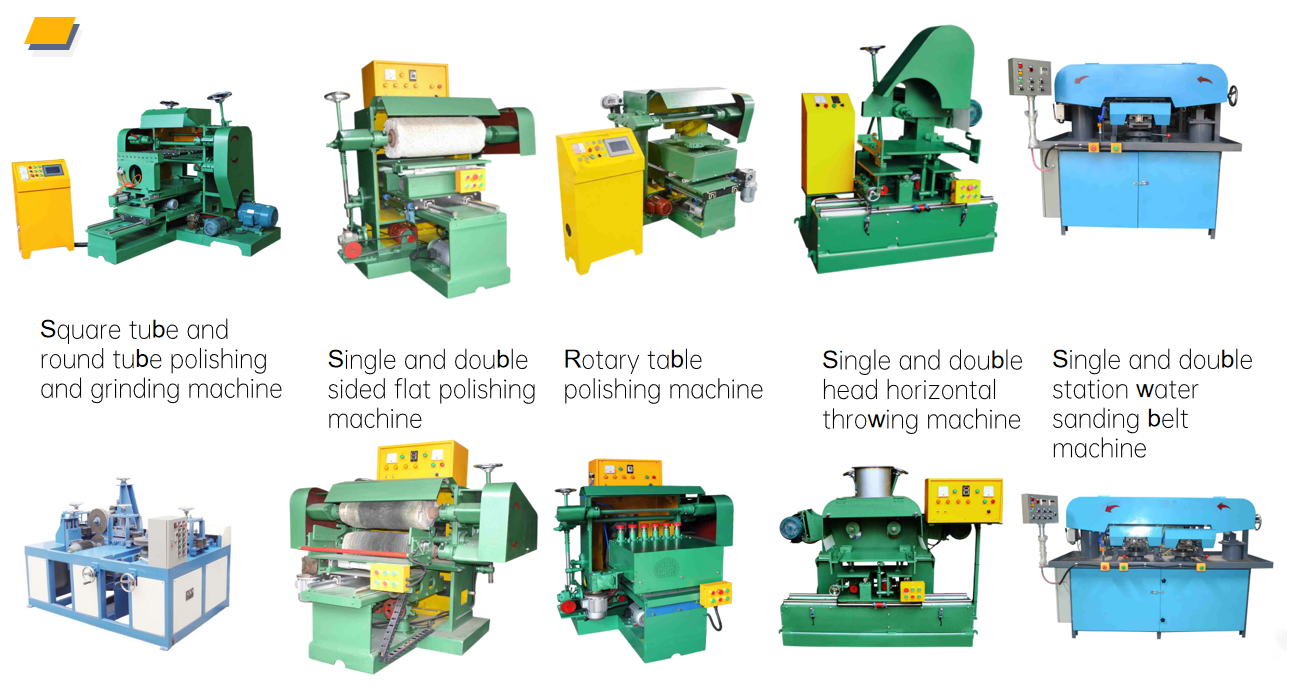

Conventional polishing and grinding equipment

Can be customized according to requirements: fully automatic function, automatic wax spray, water grinding, appearance design, equipped with robot loading, equipped with dust treatment equipment.

It is also possible to configure a flow production line with an overall polishing and polishing process according to the product process.

Manual DIY grinding equipment

Can be customized: frequency conversion adjustment, high speed above 8000, automatic waxing of solid wax, dust treatment equipment, appearance design, equipped with robot polishing.

Manual DIY grinding equipment

Can be customized: frequency conversion adjustment, high speed above 8000, automatic waxing of solid wax, dust treatment equipment, appearance design, equipped with robot polishing.

Polishing cloth wheel: Cloth wheels of different specifications can be customized according to process and equipment requirements.

Polishing cloth wheel: Cloth wheels of different specifications can be customized according to process and equipment requirements.

polishing sisal wheel

Sisal polishing wheels of different specifications can be customized according to process, product requirements, and equipment requirements.

Solid polishing wax & liquid polishing wax

Solid polishing wax & liquid polishing wax

Coated abrasive cloth products

Can be customized according to product requirements: abrasive cloth, sandpaper, abrasive belts, emery cloth wheels and other polishing products.

Nonwoven nylon products

Nonwoven nylon products

Can be customized according to product requirements: non-woven fabric sheets, flying wing wheels, non-woven grinding wheels and other non-fabric products of different specifications.

Professional service content

Professional service content

1. Free professional polishing and polishing solutions (polishing process, consumable configuration, equipment configuration) according to the product

2. Free proofing service (assist customers in process testing and polishing, bring products to us to help test the process, and create product surface effects)

3. Customize various polishing consumables (regular and special-shaped polishing wheels).

4. Customize polishing and grinding machines according to requirements.

Equipment customization process:

Provide free preliminary polishing process plan - customized equipment quotation (according to customer requirements) - drawing plan and technical agreement (customer signature to confirm) - production according to the drawing - machine adjustment in the production factory (use customer products to trial production and adjust the machine, customer confirms the production product Passed and machine acceptance) - shipment (equipped with text and video usage, installation instructions) - customer factory installation and adjustment (engineers are sent for training and usage).

Want to know more, please contact us

whatsapp:86-13928855603 / 86-18022412083

Polishing cloth wheel

Polishing cloth wheel

Stainless steel round tube polishing machine purchase and use and working principle

Stainless steel round tube polishing machine purchase and use and working principle

How to pay attention to the maintenance of the automatic polishing machine when overhauling

How to pay attention to the maintenance of the automatic polishing machine when overhauling

Polishing machine installation operation matters why deburring work

Polishing machine installation operation matters why deburring work