Specification introduction

A.equipment technical data:

1、Suitable for:stainless steel plate/roll.

2、quality of material:2B,BA sheet series,inport stainless steel sheet/roll.

3、thickness of sheet/roll;0.4—2.0mm ;

4、width of sheet/roll:maximum 700mm

一、end product parameter:mirror steel sheet 8K surface.

二、operating principle:manual feed stainless steel plate/roll and locate position,electrical grinding sides of stainless steel,manual set sheet/roll.

三、equipment and other parameter.

1、700 type 128 grinding heads 8K machine 1 set.

2、power:380V/50Hz(3 phase);

3、Installed capacity:about 180KW(each);

4、Driver motor:main motor(speed regulating motor)YCT--7.5KW 、1set;

Grinding head motor Y6--2.2KW、56set;Y6--3KW、8set

Swing motor Y6--1.5KW、16set;

Lifting motor Y4--1.5KW、16set;

5、Covered area:approx length 50meters、width 5meters;

6、assembly line direction:undetermined.

7、operator:technician 1 person,worker 2 person.

8、Equipment color:green

B.equipment composition

1、700 type 128grinding heads 8K machine 1set(6 group start grinding(one group including 8 grinding heads) +10 group start grinding(one group including 8 grinding heads),rubber pushing stainless steel rolls distance 810mm..

2、washing machine 1set(wash two parts,have 6 light tubes baking stainless steel);

3、double rolls plastic covered stainless steel machine 1 set;

4、including a Direct pumping acid drum, acid pump

C.rack structure:square tubes,Channel steel, angle iron, steel plate, welding composition

D.grinding head equip

1、Seamless tube outer seat with stainless steel grinding head shaft, bearing, gland oil seal

2. Grinding head drive: motor, V-belt drive;

3. Grinding head adjustment method: electric adjustment of turbine gearbox;

E. Plate drive adjustment device

1. Driven by rubber roller, the diameter of rubber roller is 150mm;

2. Drive mode: connected under the transmission shaft of the turbine box, driven by a speed-regulated motor;

3. Adjustment method: screw, spring adjustment;

F. Grinding head swing device

1. Horizontal, sliding plate, motor reducer drive;

2. Adjustment method: screw adjustment;

G. Lamination device

1. Laminating roller: rubber rubber roller;

2. Drive mode: turbine box, motor, chain drive

3. Operation method: manual positioning, electric film coating, artificial film unloading;

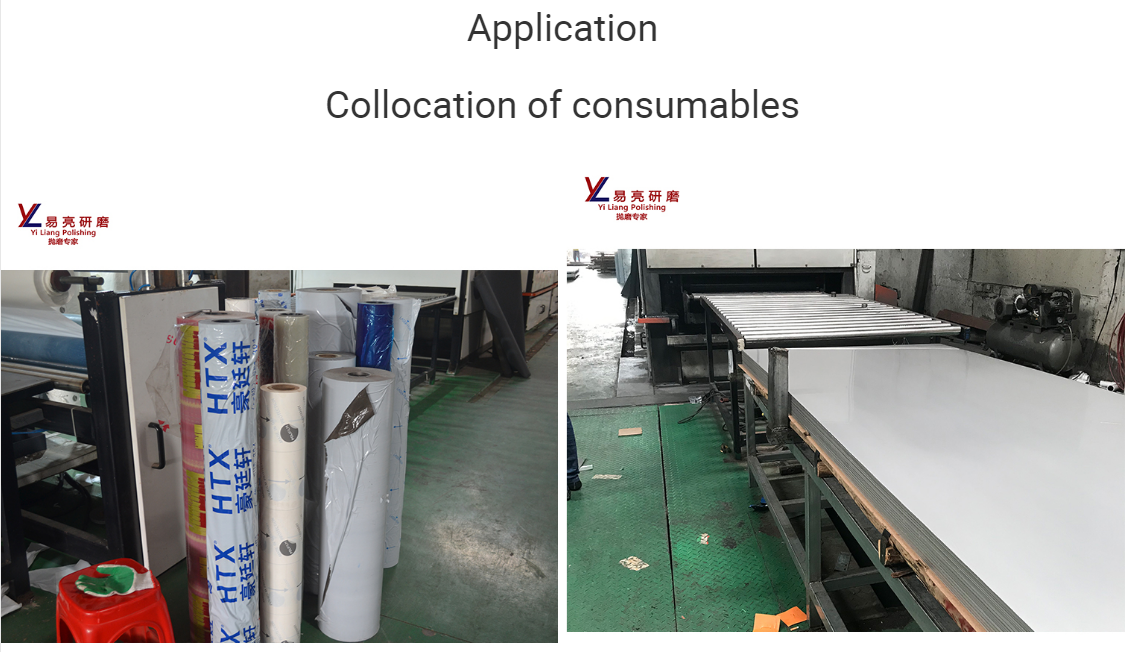

H.Feeding device

1. Feeding roller table: PE pipe;

2. Positioning method: manual operation of positioning wheel;

I. Control device: manual operation

J. Water and electricity supporting devices

1. The buyer provides water to the equipment interface;

2. The buyer is responsible for leading the power supply to the main operation box;

3. The buyer prepares acid, iron oxide red powder, blanket, sponge;

4. The buyer shall provide the necessary materials and related auxiliary tools and equipment for debugging;

K. Basic engineering of mechanical equipment

1. The basic plan of the equipment shall be provided to the buyer within 20 days after the seller signs the contract;

2. The purchaser is responsible for the construction supervision of all the basic works set up;

L.Production workshop (conditions provided by the buyer)

1. The length of the production line process layout is about 50 meters;

2. Production workshop area: 1 set of production line has a length of 50 meters x 10 meters wide x 6 meters high at the bottom;

Equipped with load-carrying cranes and supporting equipment that should be in the production workshop;