YL-ATPM-007 double axis plane surface polishing machine is suitable for all kinds double flat surface grinding and polishing at the same time. Like metal sheet and dinnerware before forming.

Technical Parameters

| Buff drive | Crosswise swing | Move in and out | Buff Opening and Closing | |

| Motor Power(2 pcs) | 5.5KW-4*1 | 250W-4*1 | 370W-4*1 | tapered motor 0.4KW-4*1 |

| Reduction Box | WPA40-20 | WPS60-60 | WD47-30 | |

| Voltage | 380V,50HZ | |||

| Spindle Speed | 1800-2200 r/min | |||

| Grind time | 0-3 minutes | |||

| Machine Size | 1500MM*1500MM*1300MM(L*W*H) (Depended on the machine size.) | |||

| Weight | 1250KG (Depended on the machine size.) | |||

| Spindle Length | 600MM | |||

| Grind area | 580MM*400MM(L*W)(allowed custom-made as your request) | |||

| Application | Suitable for all kinds flat surface grinding and polishing. Like metal sheet and dinnerware before forming. Also use for many kinds of materials, such as metal, stainless steel, alloy, iron, copper, aluminum, brass, and so on. | |||

| Match Abrasive Tools | Cotton cloth polishing, ssalgrinding wheel, non-woven deburring wheel, flap grindingwheel and ect. | |||

| Customized | The machine color, grind area size, volatage (380V, 410V, 420V, 440V) can be customized as your request. | |||

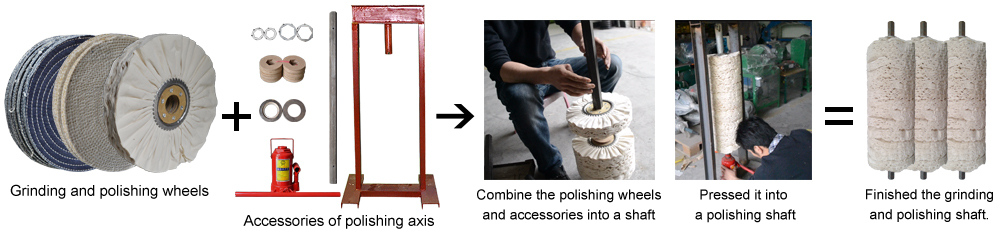

1.Install the grinding and polishing wheels into polishing shaft.

2.Install the polishing shaft on the double plane surface grinding machine. Then begin to buffing the metal products double flat surface at the same time.

2.Install the polishing shaft on the double plane surface grinding machine. Then begin to buffing the metal products double flat surface at the same time.

Feature

1.For double sides polishing and grinding of various kinds of plate metal products like Dinnerware,Hardware,Electroplating Industry.

2.Reliable performance and easy operation and maintenance with mechanical driver, wheel gear and rack rather than Silk porch, and Reliable electric cabinet with imported original master device.

3. Additional buffs emergency brake control system, well protection with your workers.

4. Easy manipulated and fixed with mechanical drive and with imported original electric cabinet.

5. Workbench has slightly swing from side to side, in order to reduce the bad effect caused by wiredrawing.

6. Grinding time can be adjusted, makes the milling time is more flexible.